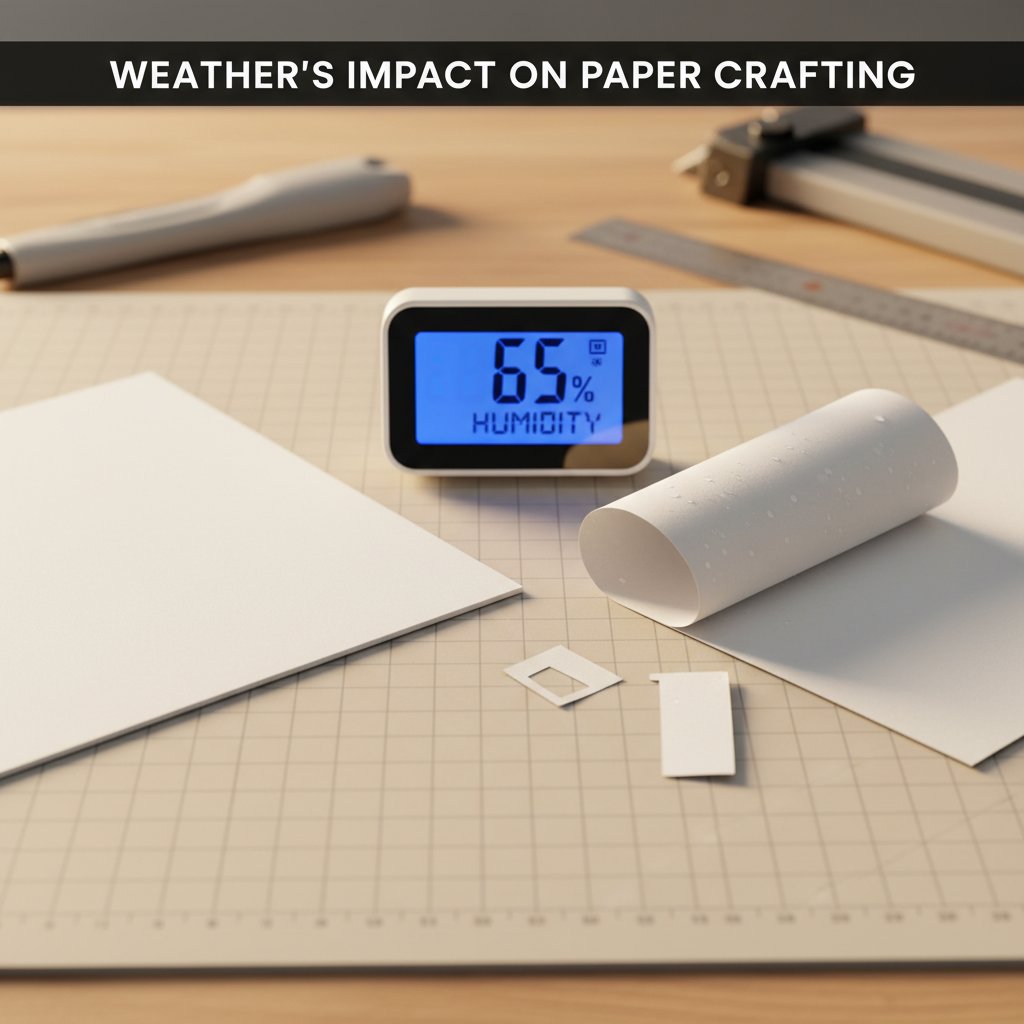

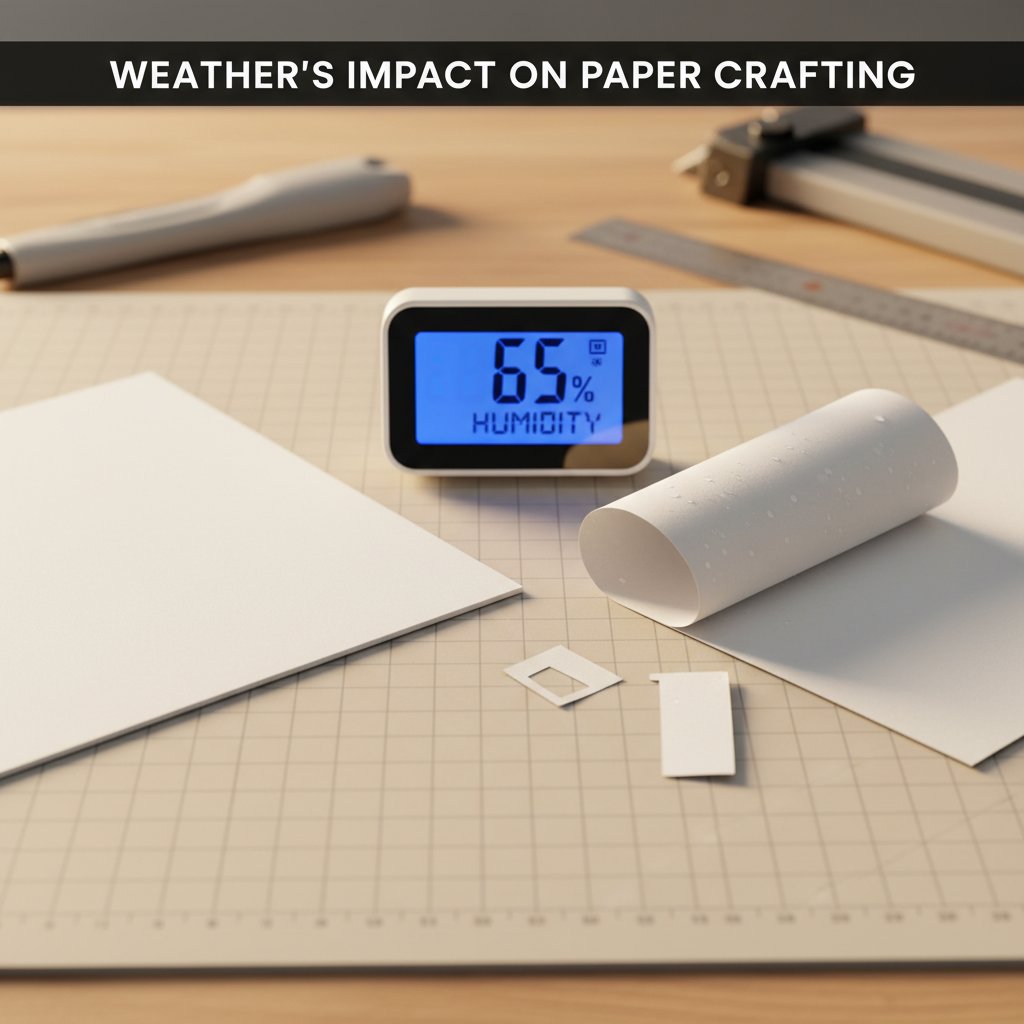

High Humidity Solutions

When humidity climbs above 60%, paper absorbs moisture and becomes difficult to cut cleanly. These

strategies

counteract moisture-related cutting problems.

Control Your Environment

Run a dehumidifier in your crafting space for at least 30 minutes before cutting. This reduces

ambient moisture

that paper absorbs. Target 45-50% relative humidity on your hygrometer for optimal results.

Air conditioning serves double duty by cooling and dehumidifying simultaneously. Even if you're

comfortable

with the temperature, running AC while cutting improves paper stability.

Prepare Your Materials

Store cardstock in sealed plastic bins with silica gel packets between uses. This prevents moisture

absorption

before cutting begins. For shadow box projects requiring multiple cardstock colors, this protection is

essential.

Pre-condition paper by placing it in your climate-controlled craft room for 24 hours before cutting.

Paper needs

time to equilibrate to room conditions after coming from storage or shipping.

Use a fan to create gentle air circulation across your cutting mat during operation. This evaporates

surface

moisture without disturbing the paper position.

Adjust Cutting Settings

Increase blade depth by one setting compared to normal conditions. Moisture-softened paper requires

deeper blade

penetration for complete cuts.

Slow down cutting speed by 20-30%. Humid paper needs more time for the blade to separate fibers

cleanly rather

than tearing through.

Add a second pass for intricate shadow box designs. The first pass scores through moisture-laden

fibers; the

second completes the cut.

Mat Management

Replace your mat more frequently during humid months. Moisture accumulation degrades adhesive faster

than normal

wear. A fresh mat provides the firm hold necessary despite humidity challenges.

Clean mats with isopropyl alcohol before each project during humid weather. This removes moisture

buildup along

with dust and fiber residue.

Store mats flat in sealed bags when not in use. This prevents environmental moisture from further

degrading

adhesive between projects.