Deep Point Blade: The Heavy Cardstock Champion

When Fine Point blades struggle, the Deep Point Blade (also called Deep Cut Blade) steps in. This

blade is

engineered specifically for thicker, denser materials that defeat standard blades.

Technical Specifications

- Blade Angle: 60 degrees

- Material: Hardened, durable steel

- Housing Color: Black

- Compatible Materials: Thick cardstock (80-110lb+), chipboard, magnet sheets, foam

sheets,

stiffened felt

- Machine Compatibility: Explore Air 2, Explore 3, Maker, Maker 3 (not Joy)

The steeper 60-degree angle provides significantly more cutting power than the Fine Point's 45

degrees. The

hardened steel construction resists dulling from abrasive materials like glitter cardstock and

metallic finishes.

Ideal Cardstock Types for Deep Point

The Deep Point blade dominates with:

- Heavy cardstock: 90lb to 110lb weight

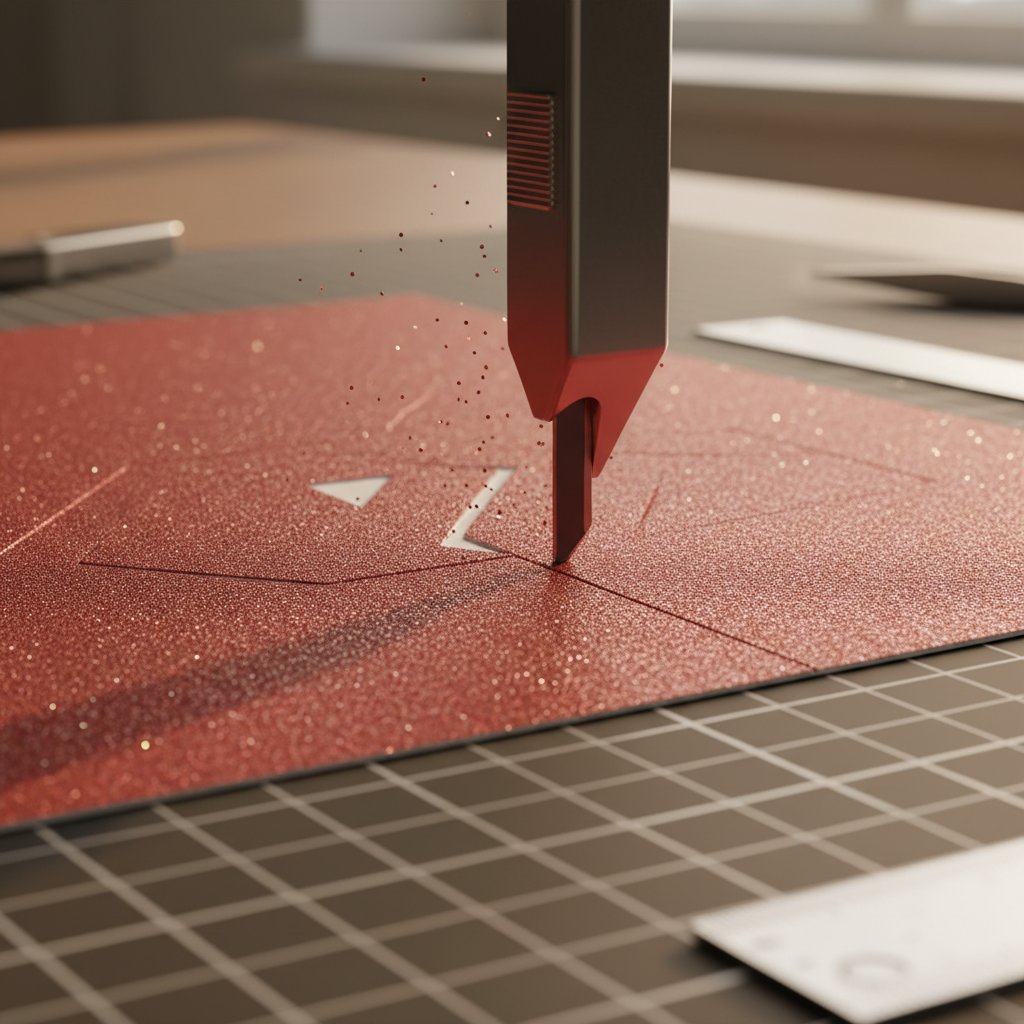

- Glitter cardstock: Any weight, especially thick glitter stock

- Metallic cardstock: Foil-finish and metallic-coated papers

- Pearl cardstock: Shimmer and pearl finishes

- Chipboard: Thin chipboard (up to 2mm)

- Textured heavy stock: Canvas, linen, embossed in heavy weights

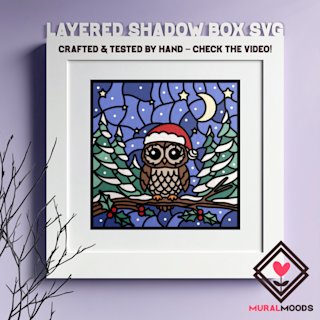

For shadow box projects using premium or specialty cardstock, the Deep Point blade cuts through in a

single pass

where Fine Point would require 2-3 passes or fail completely.

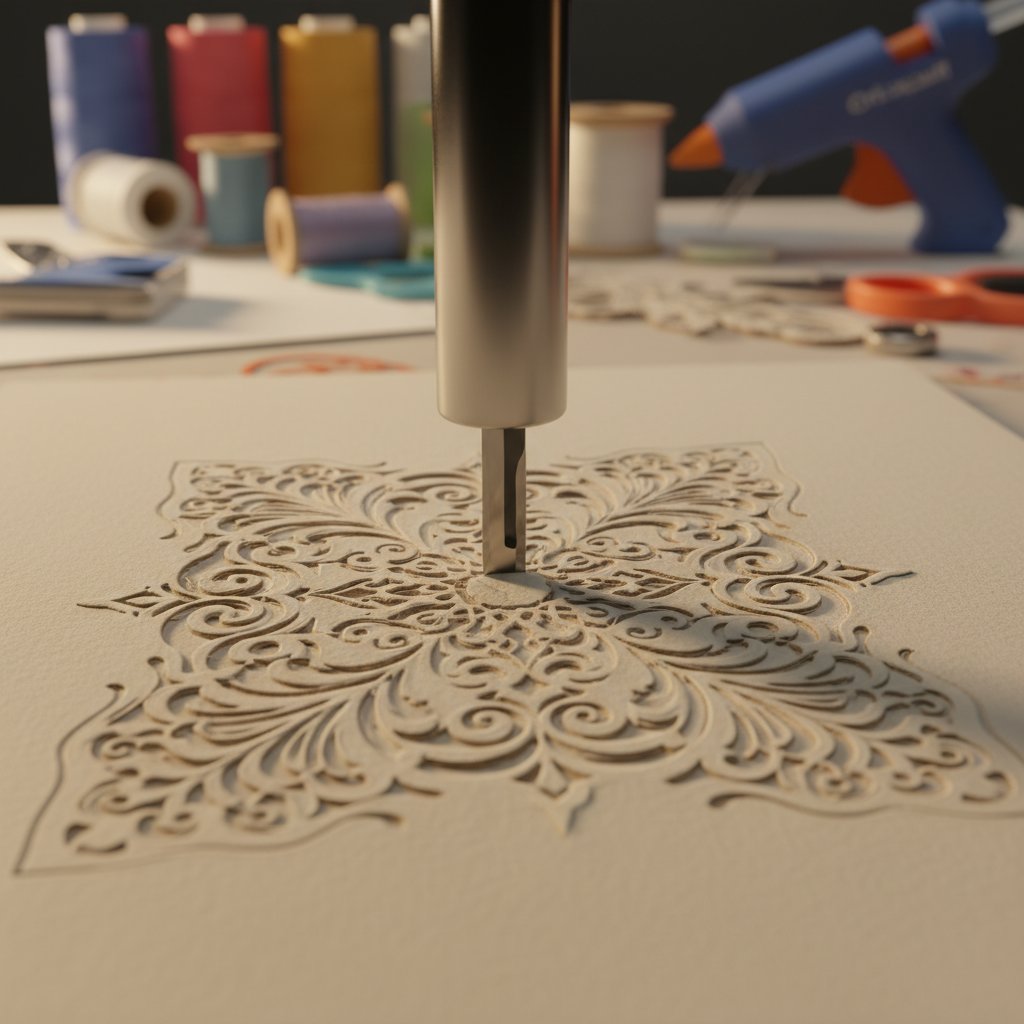

Intricate Cutting Advantages

Despite being designed for thick materials, the Deep Point blade actually excels at intricate cuts on

heavy

cardstock. The steeper angle and harder steel maintain cutting force through challenging material

without the

blade deflecting or skipping.

This makes Deep Point ideal for:

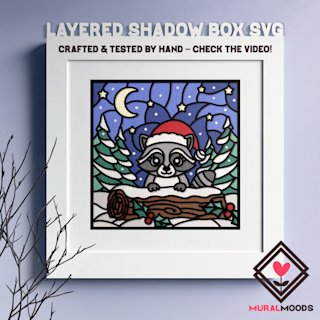

- Detailed shadow box layers in 110lb cardstock

- Intricate cuts in glitter or metallic finishes

- Fine linework in thick textured cardstock

- Small internal cuts and narrow negative spaces

The Fine Point blade may technically have a "sharper" point, but the Deep Point's

superior cutting

force translates to cleaner results on resistant materials.

Pros for Cardstock Projects

Single-Pass Cutting: Cuts thick cardstock (80-110lb) in one pass instead of

requiring multi-cut

settings, reducing mat shifting and improving alignment.

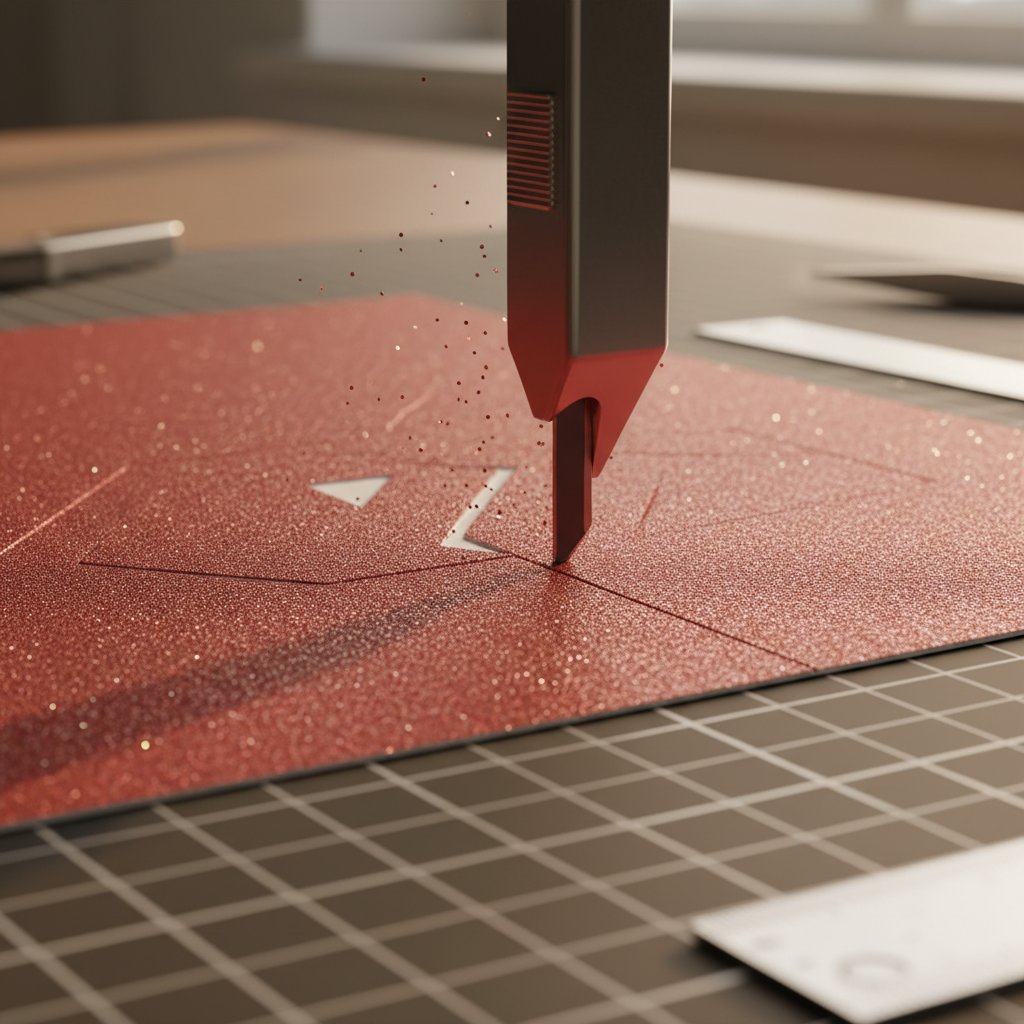

Glitter and Metallic Mastery: The hardened steel resists dulling from abrasive

glitter and

metallic coatings, lasting 3-5x longer than Fine Point on these materials.

Consistent Pressure: The 60-degree angle maintains cutting force through dense paper

fibers,

eliminating the "partially cut" problem.

Reduced Blade Deflection: Harder steel and steeper angle prevent the blade from

bending or

skipping on tough materials.

Cons and Limitations

Overkill for Light Cardstock: Using Deep Point on 65lb cardstock is like using a

chainsaw to

slice bread—it works, but you risk over-cutting and damaging delicate details.

Higher Cost: Deep Point blades cost $15-20, about 50% more than Fine Point blades.

Machine Compatibility: Not compatible with Cricut Joy, limiting users of smaller

machines.

Faster Wear on Soft Materials: The aggressive cutting action can actually dull

faster on very

soft materials compared to the gentler Fine Point.

When to Upgrade from Fine Point

Switch to the Deep Point blade when you experience:

- Incomplete cuts on cardstock over 80lb (Design Space pressure maxed but still not cutting through)

- Rapid blade dulling when cutting glitter or metallic cardstock

- Frayed or rough edges on thick cardstock (blade deflecting instead of cutting cleanly)

- Need for 3+ passes on standard settings (mat shifting becomes a problem)

- Consistent tearing at connection points on heavy materials

If you primarily work with thick or specialty cardstock for shadow boxes, investing in a Deep Point

blade saves

time, reduces waste, and delivers professional results.

Recommended Settings

For optimal Deep Point blade performance:

- Material Setting: "Cardstock, Heavyweight" or "Poster Board"

for 90-110lb

- Pressure: Start at "Default" (blade's power compensates); increase

to

"More" only if needed

- Multi-Cut: Rarely needed for cardstock; use for chipboard only

- Mat: StandardGrip (green) for most heavy cardstock; StrongGrip (purple) for

glitter or

metallic finishes