Perfect Machine Settings: Cricut

and

Silhouette Recommendations

Getting the exact right settings for metallic and pearl cardstock eliminates 90% of cutting problems.

Here's

what works for both major cutting machine brands.

Cricut's material library includes several settings optimized for specialty cardstock. Start with

these

baseline recommendations:

For heavy metallic foil cardstock: Select the Foil Poster Board

setting. This

applies appropriate pressure and blade depth for thick metallic materials while protecting the coating

from

tearing.

For lightweight shimmer and pearl papers: Choose the Pearl Paper

setting. This

works perfectly with light-weight shimmery frosted metallic papers and subtle iridescent finishes.

For medium weight metallic cardstock (65-80 lb): Start with Medium

Cardstock

setting and use the pressure dropdown to fine-tune. Many crafters find that medium cardstock at

"More"

pressure gives cleaner cuts on metallic finishes.

For intricate shadow box layers: Select Cardstock for Intricate

Cuts. This

setting automatically performs two passes at moderate depth, perfect for detailed designs that need

clean cuts

without blade gouging.

For cardstock heavier than 80 lb: Enable the double-cut or multi-cut

2x option.

This tells your machine to cut the same path twice, ensuring complete cuts through thick metallic

materials

without increasing pressure to damaging levels.

Pressure Adjustment Strategy

Cricut's pressure dropdown on the final cut screen is your secret weapon for metallic cardstock

perfection.

The dropdown allows you to specify Less, Default, or More pressure:

- Start with Default and test

- If cuts aren't complete, increase to More

- If coating is tearing or edges are rough, decrease to Less

- Make small adjustments and test between changes

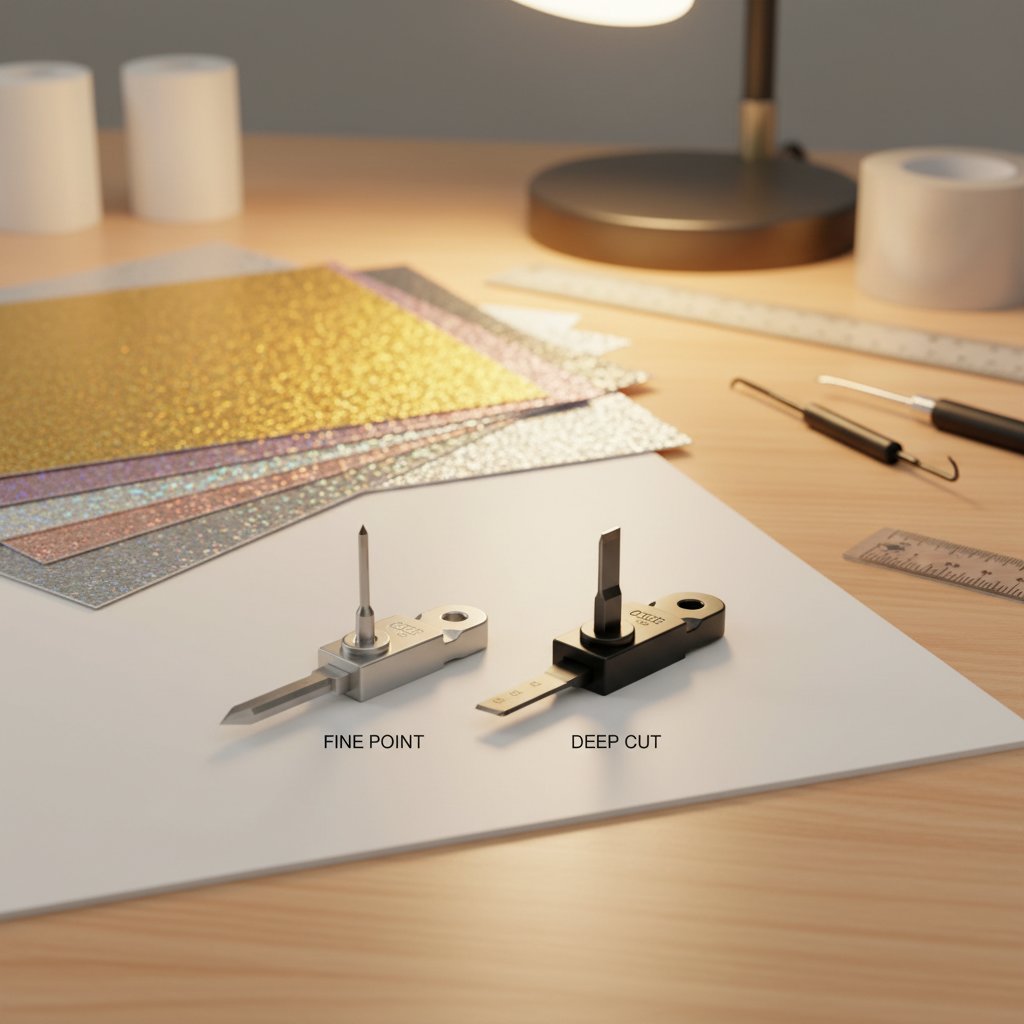

Silhouette machines use blade depth, force, and speed settings instead of material presets.

Here's the

winning combination for specialty cardstock:

For 65-80 lb metallic cardstock:

- Blade depth: 6

- Speed: 4

- Force: 8-10

- Passes: 2 (double cut enabled)

For pearl and shimmer papers:

- Blade depth: 5

- Speed: 5

- Force: 7-9

- Passes: 1-2 depending on weight

For glitter cardstock (similar properties to pearl):

- Blade depth: 6

- Speed: 4

- Force: 10

- Passes: 2 (auto double cut recommended)

Advanced Silhouette Adjustments

If standard settings aren't working, try these refinements:

Add Line Segment Overcut: This feature extends each cut slightly beyond the

endpoint, ensuring

corners and intersections cut completely through. Find it in the cutting settings advanced menu.

Increase Passes: Rather than increasing force, add an additional pass. Three passes

at moderate

force often produce cleaner results than one pass at maximum force on delicate metallic coatings.

Adjust speed: Slower speeds (3-4) give the blade more time to penetrate metallic

coatings

without tearing. Faster speeds can cause skipping on slippery surfaces.